- How Piston Engines Work

- The Four-Stroke Cycle

- Piston Engine Components

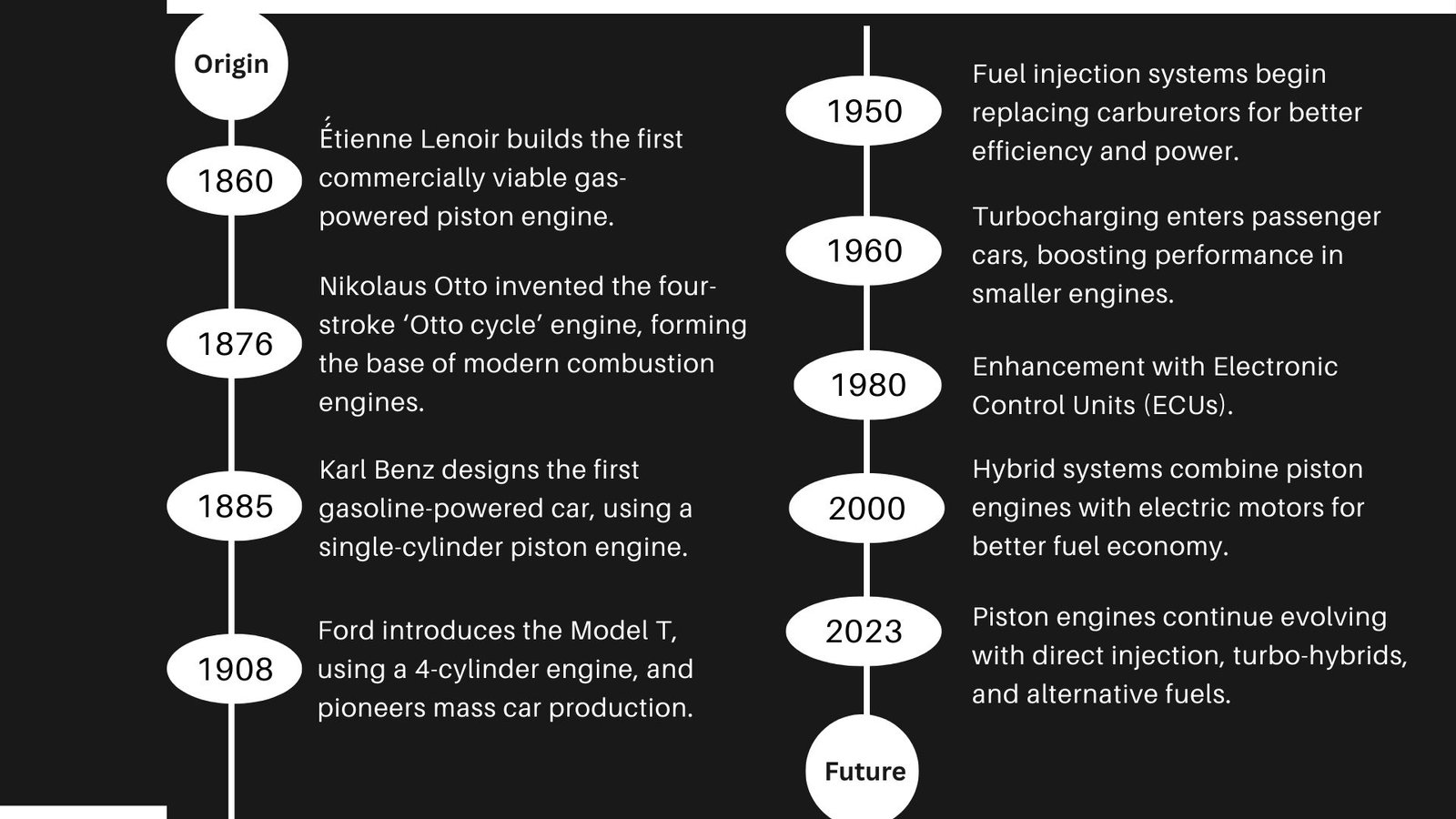

- Evolution of Piston Engines

- Engine Configurations

- Piston Engine Pros

- Piston Engine Cons

- How Rotary Engines Work

- The Rotary Cycle

- Rotary Engine Components

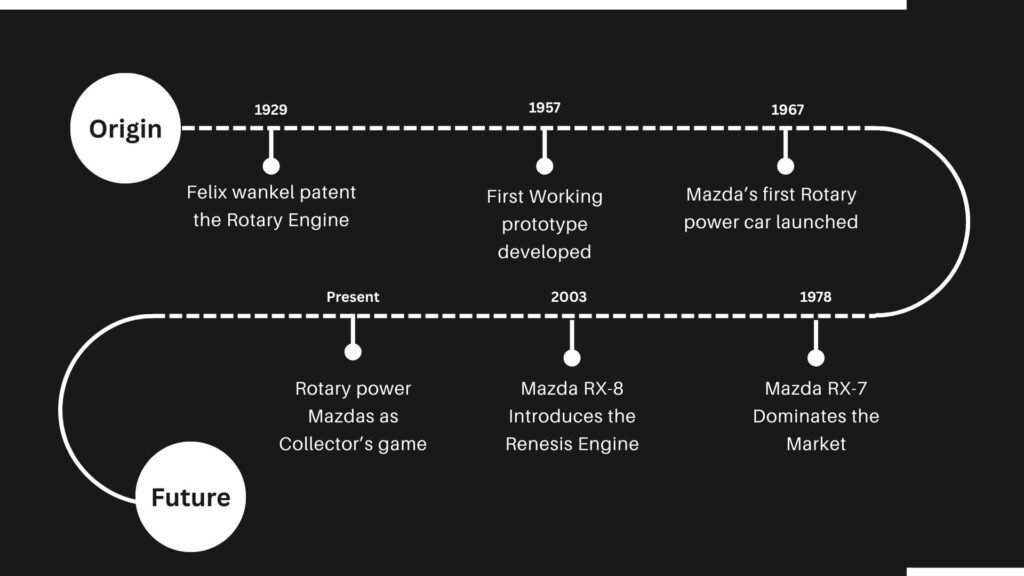

- Rotary Engine History

- Rotary Engine Pros

- Rotary Engine Cons

- Piston vs. Rotary: Head-to-Head

- Choosing the Right Engine

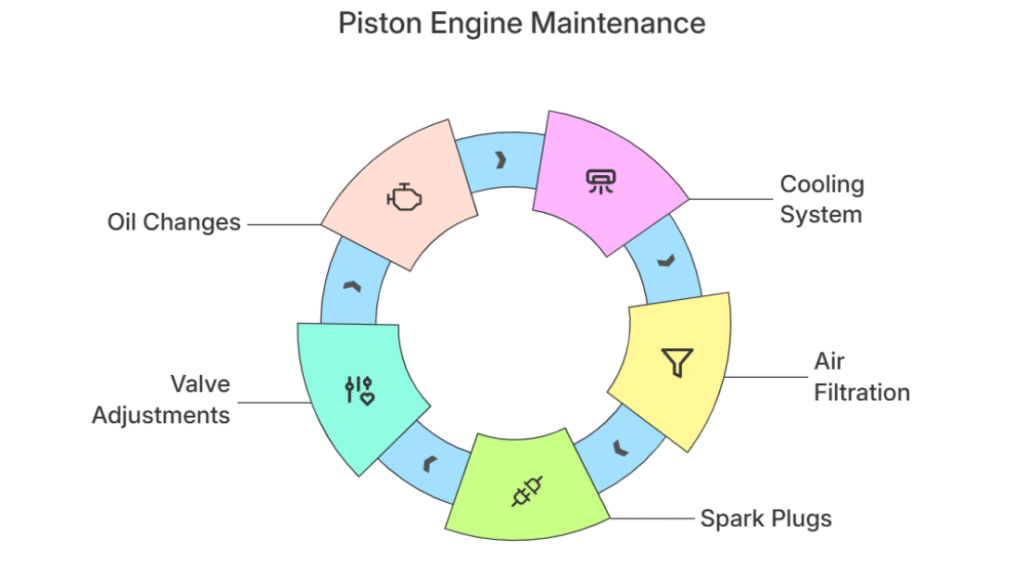

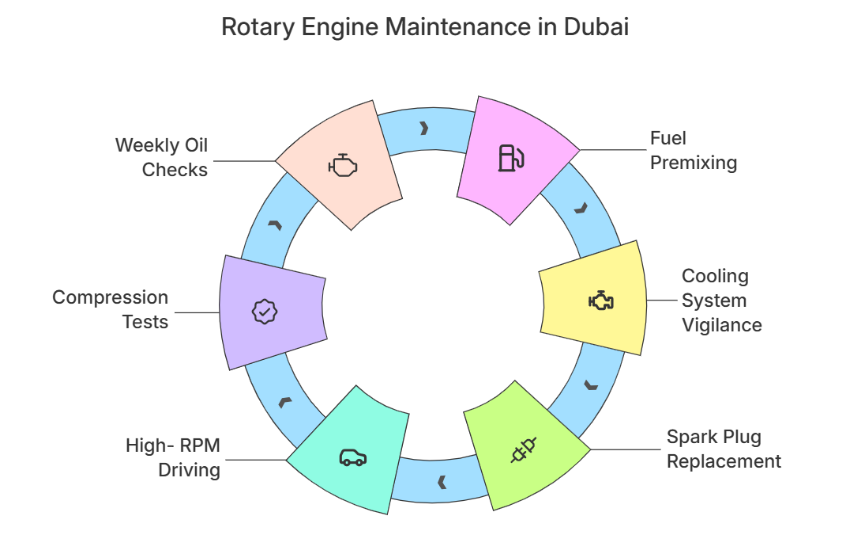

- Engine Care in Dubai’s Climate

- Noorhan TRDG: Your Parts Partner

- The Future of Engines

When it comes to internal combustion engines that power vehicles across Dubai’s expansive highways and city streets, two distinctive designs have shaped automotive history: the conventional piston engine and the innovative rotary (Wankel) engine. At Noorhan, Dubai’s premier automotive parts supplier, we understand that knowledge is power – especially when it concerns what powers your vehicle.

Whether you’re cruising Sheikh Zayed Road in a Toyota Land Cruiser, maneuvering a BMW through Jumeirah’s streets, or maintaining a classic Mazda RX-7, understanding the fundamental differences between these engine types helps you make informed decisions about performance, maintenance, and parts replacement.

This comprehensive guide explores the mechanics, advantages, limitations, and ideal applications of both engine types, giving you the insights needed to appreciate the engineering marvel under your hood.

How Piston Engines Work

The piston engine, also called a reciprocating engine, has been the dominant automotive power source for over a century. Its working principle involves converting fuel energy into mechanical motion through a series of controlled explosions.

The Four-Stroke Cycle Explained

Most modern piston engines operate on the four-stroke cycle:

- Intake Stroke: The piston moves downward while the intake valve opens, drawing an air-fuel mixture into the cylinder.

- Compression Stroke: Both valves close as the piston moves upward, compressing the mixture.

- Power Stroke: The spark plug ignites the compressed mixture, creating an explosion that forces the piston downward, generating power.

- Exhaust Stroke: The exhaust valve opens while the piston moves upward again, expelling burnt gases.

This cycle repeats thousands of times per minute, with the pistons’ linear motion converted to rotational force by the crankshaft, ultimately turning the vehicle’s wheels.

Key Components

A typical piston engine contains several critical components:

- Engine Block: The main structure housing the cylinders

- Cylinders: The chambers where combustion occurs

- Pistons: Metal components that move up and down within the cylinders

- Connecting Rods: Link pistons to the crankshaft

- Crankshaft: Converts linear piston motion into rotational motion

- Valves: Control the flow of gases in and out of the cylinders

- Camshaft: Operates the valves at precise timing intervals

- Spark Plugs: Ignite the air-fuel mixture (in gasoline engines)

Evolution of Piston Engine

Piston Engine Configurations

Piston engines come in various configurations, each with distinct characteristics:

- Inline (Straight) Engines: Cylinders arranged in a single row (e.g., inline-four, inline-six)

- Advantages: Simpler design, easier to manufacture, smoother operation (especially inline-six)

- Applications: Common in most passenger cars, particularly from European manufacturers

- V-Engines: Cylinders arranged in two banks at an angle (e.g., V6, V8, V12)

- Advantages: Shorter, more compact design for the same number of cylinders

- Applications: Performance cars, luxury vehicles, SUVs popular in Dubai

- Flat (Boxer) Engines: Cylinders arranged horizontally opposite each other

- Advantages: Lower center of gravity, natural balance

- Applications: Porsche, Subaru, and certain BMW motorcycles

- W-Engines: Essentially two V-engines joined together

- Advantages: Very compact for their cylinder count, impressive power

- Applications: High-end luxury cars from Volkswagen Group, like Bentley

Advantages of Piston Engines

Piston engines have dominated the automotive landscape for good reasons:

- Proven Reliability: Decades of engineering refinement have created exceptionally dependable designs capable of 300,000+ kilometers with proper maintenance.

- Fuel Efficiency: Modern piston engines with technologies like direct injection, variable valve timing, and turbocharging achieve impressive fuel economy – a significant advantage in Dubai, where long-distance driving is common.

- Widespread Expertise: Finding qualified mechanics for piston engine repairs is easy throughout Dubai and the UAE.

- Parts Availability: Components for brands like Toyota, Nissan, BMW, and Mercedes are readily available through suppliers like Noorhan TRDG.

- Torque Characteristics: Piston engines, especially larger displacement versions, deliver strong low-end torque ideal for everyday driving conditions.

- Adaptability: Can be configured in various layouts (inline, V, flat) and sizes to suit different vehicle types and performance requirements.

- Cost-Effectiveness: Lower manufacturing costs translate to more affordable vehicles and maintenance.

Limitations of Piston Engines

Despite their ubiquity, piston engines have inherent drawbacks:

- Mechanical Complexity: Dozens of moving parts create multiple potential failure points.

- Size and Weight: The reciprocating assembly, valve train, and supporting components result in larger, heavier packages compared to equivalent power rotary designs.

- Vibration: The up-and-down motion of pistons generates inherent vibration that requires counterbalancing.

- RPM Limitations: Most piston engines have relatively low redlines (typically 6,000-7,000 RPM for production cars) due to valve float and inertia constraints.

- Power Density: Generally provide less power per unit of weight/size compared to rotary engines.

How Rotary Engines Work

The rotary (Wankel) engine represents a radical departure from conventional piston design. Instead of reciprocating motion, it uses rotational motion to generate power.

The Unique Rotary Cycle

Inside a rotary engine:

- A triangular rotor spins within an oval-shaped housing (epitrochoid).

- The rotor’s three faces create separate chambers that expand and contract as it rotates.

- As each chamber changes volume, it performs the same four functions as a four-stroke piston engine: intake, compression, power, and exhaust.

- The rotor connects to an eccentric shaft (equivalent to a crankshaft), transferring rotational energy to the drivetrain.

One complete revolution of the rotor completes three power cycles – making a single-rotor Wankel roughly equivalent to a three-cylinder piston engine in power pulses.

Essential Components

The rotary engine features remarkably few major moving parts:

- Rotor Housing: The epitrochoid-shaped chamber where combustion occurs

- Rotor: The triangular component that rotates inside the housing

- Apex Seals: Critical components at the rotor’s three tips that maintain compression

- Eccentric Shaft: Converts the rotor’s motion into usable rotational force

- Side Seals: Seal the sides of the rotor against the end plates

- Stationary Gears: Control the rotor’s orbital path

- Oil Metering Pump: Delivers oil to lubricate apex seals (a unique feature of rotary engines)

The History of Rotary Engines

The rotary engine concept was patented by German engineer Felix Wankel in 1929, with the first working prototype developed in 1957. Though various manufacturers experimented with the technology (including NSU, Citroen, and Mercedes-Benz), Mazda made the most significant commitment to rotary engines, refining the design for production vehicles.

Mazda introduced its first rotary-powered car, the Cosmo Sport, in 1967. The company’s most famous rotary models include:

- Mazda RX-7 (1978-2002): A sports car that evolved through three generations, with the final FD3S model featuring a sequential twin-turbocharged 13B-REW engine

- Mazda RX-8 (2003-2012): A four-door sports car with the naturally-aspirated RENESIS rotary engine

These vehicles have cultivated dedicated followings in Dubai’s automotive enthusiast community, with well-maintained examples commanding premium prices in the UAE’s used car market.

Advantages of Rotary Engines

The rotary design offers several compelling benefits:

- Exceptional Compactness: Rotary engines are significantly smaller and lighter than equivalent-power piston engines – typically half the weight and size.

- Mechanical Simplicity: With just three primary moving parts per rotor (compared to dozens in piston engines), there’s less mechanical complexity.

- Smooth Operation: The continuous rotational motion eliminates the vibration inherent in reciprocating piston engines.

- High-Revving Capability: Rotary engines can safely operate at very high RPMs (9,000+ RPM) due to the absence of valve trains and reciprocating mass.

- Power Density: Impressive power output relative to their compact dimensions and weight.

- Distinctive Character: The unique sound profile and smooth power delivery create an unmistakable driving experience prized by enthusiasts.

- Durability Against Catastrophic Failure: Unlike piston engines, rotary engines rarely experience sudden, catastrophic failures – they typically degrade gradually with compression loss.

Limitations of Rotary Engines

Despite their elegance, rotary engines have faced significant challenges:

- Sealing Difficulties: Maintaining compression at the apex seals presents an ongoing engineering challenge, affecting reliability and longevity.

- Fuel Efficiency: Rotary engines typically consume more fuel than comparable piston engines due to their elongated combustion chamber shape.

- Oil Consumption: Most rotary designs intentionally inject oil into the combustion chamber to lubricate apex seals, resulting in higher oil consumption.

- Emissions Challenges: The combustion chamber shape leads to higher hydrocarbon emissions and has made meeting modern emissions standards difficult.

- Specialized Knowledge: Fewer mechanics in Dubai and worldwide possess rotary engine expertise.

- Heat Management: The concentrated combustion area creates significant thermal challenges, particularly relevant in Dubai’s hot climate.

- Cold-Start Characteristics: Rotary engines can be more challenging to start in cold conditions (though less relevant in Dubai’s climate).

Direct Comparison: Piston vs. Rotary Engines

Performance Characteristics

| Aspect | Piston Engine | Rotary Engine |

|---|---|---|

| Power Delivery | Progressive, broad torque curve | Smoother, peakier at higher RPMs |

| Responsiveness | Good low-end torque | Needs higher RPMs for maximum performance |

| Redline | Typically 6,000–7,500 RPM | Often 9,000+ RPM |

| Sound | Varied (deep, throaty to high-pitched) | Distinctive high-pitched “buzz” |

| Power-to-Weight | Good | Excellent |

| NVH (Noise, Vibration, Harshness) | Higher vibration | Exceptionally smooth |

| Power per Displacement | Lower | Higher (13B ~1.3L rotary ≈ 2.6L piston) |

Practical Considerations for Dubai Drivers

| Factor | Piston Engine | Rotary Engine |

|---|---|---|

| Fuel Consumption | More efficient | Higher consumption (important in Dubai where driving distances can be significant) |

| Reliability in Heat | Good with proper cooling | More sensitive to overheating (significant in Dubai’s summer temperatures) |

| Local Expertise | Widely available across UAE | Limited to specialized shops |

| Parts Availability | Excellent through suppliers like Noorhan TRDG | More specialized, requiring dedicated suppliers |

| Longevity | 300,000+ km potential | Often shorter intervals between rebuilds |

| Maintenance Cost | Generally lower | Higher due to specialization |

| Resale Value | Predictable | Variable (collectible for certain models) |

Which Engine Suits Your Needs?

Perfect Uses for Piston Engines

Piston engines excel in numerous applications, particularly those requiring:

- Everyday Reliability: Family sedans, SUVs, and trucks benefit from the proven dependability of piston designs.

- Fuel Efficiency: Long-distance cruising across the Emirates is more economical with piston engines.

- Diverse Power Requirements: From small economy cars to luxury SUVs common in Dubai, piston engines scale effectively.

- Towing Capacity: The strong low-end torque is ideal for hauling boats to the Gulf or desert equipment.

- Easy Maintenance: Regular service is widely available throughout the UAE.

- Low Operating Costs: Lower fuel consumption and maintenance needs benefit fleet operators and daily commuters.

Popular piston-powered vehicles in Dubai include the Toyota Land Cruiser, Nissan Patrol, BMW 5-Series, and Mercedes-Benz E-Class – all representing different approaches to piston engine design.

Perfect Uses for Rotary Engines

Rotary engines find their niche in specialized applications:

- Sports Cars: The high-revving nature and compact dimensions make them ideal for performance vehicles.

- Weight-Sensitive Applications: When power-to-weight ratio is critical.

- Unique Driving Experience: For enthusiasts seeking something different from the mainstream.

- Space-Constrained Designs: When engine bay dimensions are limited.

- Racing Applications: Their smooth power delivery and high-revving capability suit certain motorsport categories.

The most famous rotary-powered production cars are from Mazda, including the legendary RX-7 and the more recent RX-8, both of which have cult followings in Dubai’s car enthusiast circles.

Maintenance and Longevity: Keeping Your Engine Running in Dubai's Climate

Piston Engine Maintenance

In Dubai’s harsh climate, piston engines require:

- Regular Oil Changes: Every 5,000-10,000 km using high-quality synthetic oils suitable for high temperatures.

- Cooling System Maintenance: Critical given Dubai’s extreme summer heat.

- Air Filtration: Frequent replacement due to dust conditions.

- Timing Belt/Chain Service: According to manufacturer schedules.

- Spark Plug Replacement: Every 30,000-100,000 km depending on type.

- Valve Adjustments: As recommended by manufacturers.

- Fuel System Cleaning: Periodic injector and throttle body cleaning to prevent deposit buildup.

- Engine Mounts Inspection: The heat can accelerate deterioration of rubber components.

With proper maintenance, modern piston engines can easily exceed 300,000 kilometers before requiring major overhauls.

Rotary Engine Maintenance

Rotary engines demand more specialized attention in Dubai’s environment:

- Frequent Oil Monitoring: Due to designed oil consumption, levels must be checked weekly.

- Premixed Fuel: Some enthusiasts add oil to their fuel for additional apex seal lubrication.

- Cooling System Vigilance: Overheating is particularly damaging to rotary engines.

- Ignition System Maintenance: Spark plugs work harder in rotary engines and require more frequent replacement.

- Carbon Buildup Prevention: Regular high-RPM driving helps prevent carbon accumulation.

- Compression Tests: Should be performed regularly to monitor apex seal condition.

- Proper Warm-up and Cool-down: Essential to manage thermal expansion and prevent seal damage.

- Heat Management Upgrades: Often beneficial in Dubai’s climate, including improved radiators and oil coolers.

Rotary engines typically require rebuild consideration at 80,000-120,000 kilometers, primarily due to apex seal wear.

Noorhan TRDG: Your Engine Parts Solution in Dubai

At Noorhan TRDG, we understand the unique requirements of both piston and rotary engines operating in Dubai’s demanding conditions. Our comprehensive inventory includes:

For Piston Engines:

- Complete engine rebuild kits

- Pistons and piston rings

- Crankshafts and connecting rods

- Cylinder heads and valvetrain components

- Timing chains, belts, and gears

- Gaskets and sealing solutions

- Performance upgrades and OEM replacements

- Engine management sensors and components

- Cooling system parts designed for extreme heat

We supply parts for all major manufacturers including Toyota, Nissan, BMW, Mercedes-Benz, Land Rover, Ford, and more – covering everything from economy commuters to luxury performance vehicles.

For Rotary Engines:

- Apex seals and corner seals

- Rotor housings and rotors

- Eccentric shafts

- Engine rebuild kits

- Performance upgrades

- Specialized lubricants and additives

- Enhanced cooling solutions

- High-performance ignition components

- Porting services for increased power

Our rotary engine expertise extends to all Mazda rotary models, including the rare and collectible models that have passionate followings in the UAE.

Why Choose Noorhan TRDG for Engine Parts?

- Genuine and OEM-Quality Parts: We supply factory-original and premium aftermarket components.

- Technical Expertise: Our team understands the specific requirements of engines operating in Dubai’s climate.

- Comprehensive Inventory: From common service items to specialized rebuild components, we maintain extensive stock.

- Performance Options: Whether you seek reliability or enhanced performance, we offer appropriate solutions.

- Competitive Pricing: Quality parts at fair market rates for the Dubai region.

- Expert Advice: Our specialists can recommend the best components for your specific application.

- Warranty Coverage: Peace of mind with warranty on eligible parts

The Future of Engines: What's Next for Piston and Rotary Designs?

Evolving Piston Technology

Piston engines continue to advance through:

- Hybrid integration for improved efficiency

- Cylinder deactivation technology

- Variable compression ratios

- Advanced materials reducing weight and friction

- Improved thermal management

- Smart engine management systems

- Synthetic fuel compatibility

- Lean-burn technologies for reduced emissions

- Water injection systems for cooling and performance

These innovations extend the viability of piston engines even as electrification grows, ensuring they’ll remain relevant in Dubai and globally for decades to come.

Rotary Renaissance

While mainstream rotary production ended with the Mazda RX-8, the design is experiencing renewed interest:

- Mazda has reintroduced the rotary as a range extender in hybrid vehicles

- The compact dimensions make rotaries excellent generators in electrified powertrains

- Hydrogen combustion research continues with rotary engines

- Advanced manufacturing and materials science offer solutions to historical sealing challenges

- Enthusiast communities keep the technology alive through restoration and modification

- 3D printing enables new approaches to rotor housing design

- Computer-controlled direct injection improves efficiency

The unique advantages of rotary engines ensure they’ll maintain a presence in specialized applications and enthusiast vehicles.

Special Considerations for Dubai's Climate and Driving Conditions

Dubai’s unique environment creates specific challenges for engines:

Hot Climate Impacts:

- Increased cooling system demands

- Accelerated oil degradation

- Higher risk of vapor lock in fuel systems

- Faster deterioration of rubber components

- Greater stress on air conditioning (affecting engine load)

Desert Driving Considerations:

- Sand ingestion risks for air intakes

- Higher suspension loads affecting engine mounting

- Extended idle periods in traffic affecting cooling

- Long highway stretches in extreme heat

Both engine types require adaptations for these conditions, with piston engines typically offering more robust heat management in stock configurations, while rotary engines benefit from aftermarket cooling upgrades for Dubai use.

Conclusion: Choosing Your Ideal Engine

Both piston and rotary engines represent ingenious solutions to the challenge of converting fuel into motion, each with distinct characteristics that suit different applications and driver preferences.

For most Dubai drivers, the conventional piston engine offers the ideal balance of reliability, efficiency, and ease of maintenance. The wide variety of configurations – from economical four-cylinders to powerful V8s – ensures there’s a piston engine suited to virtually every automotive need.

For those seeking something extraordinary – a unique driving experience characterized by smooth, high-revving performance in a compact package – the rotary engine represents an intriguing alternative, albeit one requiring additional care and specialized knowledge.

Whichever engine powers your journey through Dubai and the Emirates, Noorhan TRDG stands ready to supply the quality parts and expertise needed to keep it running at its best. Visit our showroom or contact our team to discover how we can support your automotive needs with the region’s most comprehensive selection of engine components.

Contact Noorhan TRDG today to experience the difference quality parts make in your engine’s performance and longevity.

This comprehensive guide is brought to you by Noorhan TRDG, Dubai’s premier supplier of automotive engine parts for all makes and models. When knowledge meets quality components, your vehicle performs at its best.

Where you can buy reliable parts for engines in dubai

Piston and Rotary Engines are available at different suppliers and dealers of auto spare parts in Dubai. Noorhan is amongst the leading brands that deal with genuine auto spare parts and aftermarket parts for different car brands, including BMW, Mercedes, Audi, Porsche, Honda, Toyota, Nissan, Mazda, Jeep, Ford, and other Japanese, European, American, Korean, luxury cars brand.

If you’re looking to replace your Piston and Rotary Engines with high-quality aftermarket parts in Dubai, Noorhan can help you.